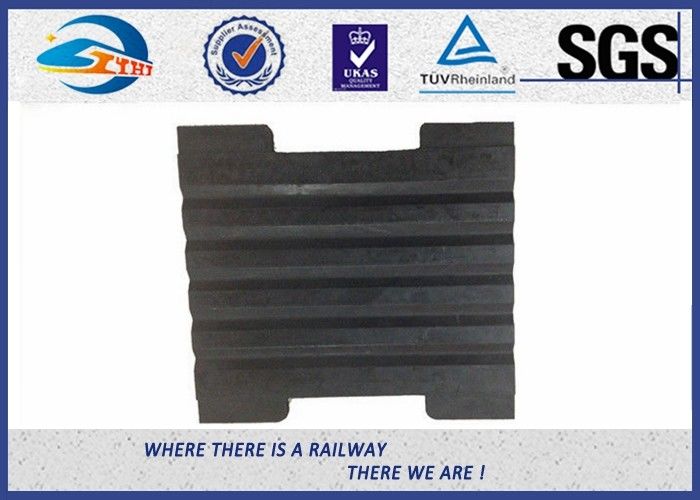

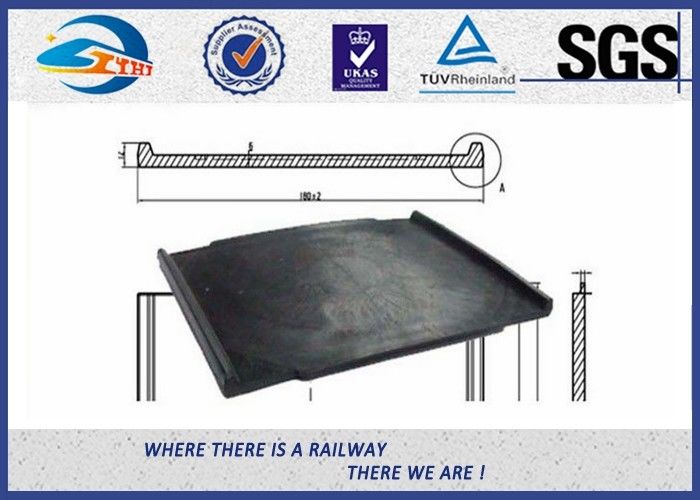

Customized Rubber Pad Plastic And Rubber Part HDPE For Railway Fastening

Rail and Support Pads

Zhongyue have been supplying track support products to the rail industry for many years.Manufactured in a

variety of natural and synthetic elastomers,

Zhongyue railpads are designed to withstand the most demanding

operating environments. SUYU railpads offer the following benefits:

1. Dramatically Improved Impact

2. Attenuation Noise Suppression

3. Improved Passenger Comfort

4. Extended Track Life

5. Extended Ballast Life

Zhongyue in a joint initiative with a major world producer of rail track fastening systems analysed and

developed a resilient pad concept to protect concrete rail sleepers from damage caused by the dynamic

forces of passing trains. The result was the Patented Studded railpad.

Over 45 Million of these rail pads are now used successfully Worldwide, including the USA, Canada,

Australia, Norway, Sweden, Denmark, Belgium, France, Georgia, Lithuania, Hong Kong, Japan, Korea,

Czech Republic, Uzbekistan, Syria, Singapore, Sudan, Estonia, Finland and extensively within the UK.

The combination of studded design and specially formulated rubber compound, gives Zhongyue patented

rail pads a unique high resilience and abrasion resistance.

Their superiority to those manufactured from other materials has been proven by their ability to reduce

dynamic forces by up to 65%, which is a crucial consideration for railway systems worldwide as they adopt

higher speeds and greater axle loads.

Test Report of Rubber (EPDM)

|

Product

|

EPDM

|

|

Specification

|

EP00179

|

|

No.

|

Item

|

Test Method

|

Required Value

|

Test Value

|

|

1

|

Shore Hardness

|

D-2240

|

60±5

|

64

|

|

2

|

Tensile Strength(Mpa)

|

D-412

|

>1.25

|

14.4

|

|

3

|

Elongation at Break(%)

|

D-412

|

>280

|

288

|

|

4

|

Permanent Compression Set

(%)

|

D-395

|

28

|

28

|

|

5

|

Tear Strength(KN/M)

|

D-624

|

/

|

43

|

|

6

|

Operating Temperature

|

|

|

-30C-100C

|

HDPE Properties

|

No.

|

Items

|

Unit

|

Technical Requirements

|

Actual Data

|

|

1

|

Density

|

g/㎝3

|

0.95-0.98

|

0.95

|

|

2

|

Tensile

|

Mpa

|

≥19

|

19

|

|

3

|

Elongation

|

%

|

>80

|

150

|

|

4

|

Melting Point

|

℃

|

170-190

|

190

|

|

5

|

Insulation Resistance

|

Ω

|

≥1×1010

|

3.5×1010

|

|

6

|

Hardness

|

A

|

≥98

|

98(A)

|

Product Photos

Factory

Certificate

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!